Your Trusted Partner for Dynamic Stainless Processing Equipment

Tell us about your process today... We strive to optimise stainless equipment.

Get in touch: 0478 049 633

Tell us about your process today... We strive to optimise stainless equipment.

Get in touch: 0478 049 633

At Dyna Pro, our vision is to be Australia's leading provider of agricultural and commercial stainless process equipment. We are committed to providing our clients with the highest quality products and services to help them succeed and grow. We will achieve this by staying at the forefront of industry trends and by continuously improving our offerings.

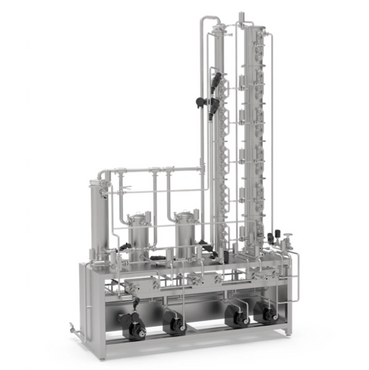

We offer a comprehensive range of industrial equipment, including pumps, agitators, heating and cooling, tanks, commercial boilers, distillation systems and other stainless processing equipment which are built to order pre fabricating as much as is practical. We are dedicated to providing our clients with reliable, durable, and efficient process solutions.

With over 20 years of experience in the industrial process equipment, the team at Dyna Pro has the knowledge and expertise to help you find the right solution for your process needs. We offer expert advise, personalised service, and ongoing support to ensure your complete project satisfaction. We take the process from concept through to commissioning.

Dynapro is an Australian company specializing in the design, manufacture, and supply of high-quality stainless steel processing equipment for various industries. They are known for their expertise in hygienic solutions, particularly for the food and beverage, pharmaceutical, and chemical sectors.

Jake is a passionate chemical engineer with broad experience in industrial stainless steel design. Coupled with an acute capacity for process optimisation, Jake efficiently nurtures projects from design conceptualisation, implementation, all the way through to commissioning.

He has over 7 years’ of hands-on industrial experience in stain

Jake is a passionate chemical engineer with broad experience in industrial stainless steel design. Coupled with an acute capacity for process optimisation, Jake efficiently nurtures projects from design conceptualisation, implementation, all the way through to commissioning.

He has over 7 years’ of hands-on industrial experience in stainless steel industrial applications, most recently specialising in small and medium scale commercial breweries, backed by a Masters in Bio-Molecular Chemical Engineering and an undergraduate degree in Metallurgical Engineering.

Over the last few years Jake developed an innovative new installation process for commercial breweries, working with manufacturers to prefabricate as much of the process line work and process electrical work as possible prior to installation.

This means a significant net reduction in installation costs, and more accurate quotes overall, due to less time spent on-site by qualified tradespeople, and fewer cost variables at the time of installation.

Jake enthusiastically pursues sustainability by continually improving the efficiency of his design work. Not only does this have a great impact on the environment, it also reduces operating costs.

Jake’s ground up understanding of stainless steel process engineering has given him a unique understanding of what works and what doesn’t work in varied industries at different scales.

Jake's ambition is to help deliver projects that exceed expectations and continuously improve industry and production processes in Australia.

Alex is a seasoned chemical engineer with a deep-rooted expertise in distillation processes. With a strong focus on continuous distillation, he brings a wealth of knowledge in optimising separation techniques for enhanced efficiency and product purity. His proficiency in designing, implementing, and troubleshooting distillation systems ha

Alex is a seasoned chemical engineer with a deep-rooted expertise in distillation processes. With a strong focus on continuous distillation, he brings a wealth of knowledge in optimising separation techniques for enhanced efficiency and product purity. His proficiency in designing, implementing, and troubleshooting distillation systems has led to successful outcomes in the craft distilling industry.

With over a decade of business and marketing experience across diverse industries, Andy brings valuable insights to the DynaPro team. His tenure as General Manager of Australia's largest B2B wholesaler and primary producer in its sector has equipped him with a deep understanding of marketing principles, commercial partnerships, and intern

With over a decade of business and marketing experience across diverse industries, Andy brings valuable insights to the DynaPro team. His tenure as General Manager of Australia's largest B2B wholesaler and primary producer in its sector has equipped him with a deep understanding of marketing principles, commercial partnerships, and international trade. This expertise enables him to strategically guide DynaPro's growth trajectory.

Andy's keen understanding of large-scale agricultural and commercial operations allows him to identify specific customer requirements and effectively communicate these needs to the DynaPro design team. He recognizes that a one-size-fits-all approach rarely succeeds in agriculture. By collaborating with customers to pinpoint the right equipment for their unique needs, Andy ensures they can optimize operations and avoid unnecessary capital expenditure. This customer-centric approach maximizes return on investment and fosters business growth.

Paige is a chemical and materials engineer who has specialised in project management. Her time as BHP's Portfolio Manager ignited her passion for PMBOK style project management. She has extensive experience in the mining industry managing a construction project portfolio of $750m.

We love our customers, so feel free to reach out!

Mon | 09:00 am – 05:00 pm | |

Tue | 09:00 am – 05:00 pm | |

Wed | 09:00 am – 05:00 pm | |

Thu | 09:00 am – 05:00 pm | |

Fri | 09:00 am – 05:00 pm | |

Sat | Closed | |

Sun | Closed |

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.